plug flow reactor pdf

This will open up COMSOL library where you see many COMSOL files to solve chemical reaction engineering problems. The plug flow reactor is more complex than the continuous-stirred tank alternative with regard to operating conditions.

Oscillatory Baffled Reactor An Overview Sciencedirect Topics

The plug flow reactor is the second-most primary ideal reactor and is similar to the continuous stirred tank bioreactor.

. Bilge Alpaslan Kocamemi If the series is composed of one reactor complete mix regime prevails If the series consists of an infinite number plug-low regime prevails. Laminar vs Plug Flow 3 Laminar flow has a distribution of speeds and residence times Plug Flow is a simplification for analysis purposes Turbulent flow is closer to plug but more wall contact. Contiguous cross-sections cannot exchange mass with each other.

Compare ideal batch and ideal PFR mass balances. In the case of tube flow the accepted ideal is the plug-flow reactor in which it is assumed that there is no mixing in the axial flow direction but perfect mixing in the directions transverse to this. 2 Uses of a PFR Add an image.

The use of static mixers could change the velocity profile in order to approach the ideal case of plug-flow. There are many equipment techniques. The polymerization of ethylene and the conversion of naphtha to ethylene are examples.

It can be shown2 that the absence of axial mixing allows the achievable reactant conversion to be maximized. Users can screen new chemistries identify new catalysts and optimise conditions on a small scale. The reactor itself may consist of an empty.

A catalytic process is used for the synthesis of ammonia. Request PDF Tubular Plug Flow Reactors This article contains sections titled. Debasree Ghosh Lecture notes on Polymer Reaction Engineering Module II.

Gas phase reaction 4A B R S is performed in a plug flow reactor. PF R The PFR model is frequently used for a reactor in which the reacting system gas or liquid flo ws at relatively. Plug Flow Reactor HernandezPine Plug Flow Reactor usually operated continuously at steady-state apart from start-up and s hutdown periods may be used for either gas-phase or liquid-phase reactions.

The reaction occurs along the flow path. A Plug Flow Reactor PFR consists in a long straight pipe in which the reactive fluid transits at steady-state no accumulation. In an ideal PFR is the absolute residence time for mass flowing through the reactor not the average residence time as in a CSTR.

This will be analyzed in the following section. The main assumptions of this model are that the fluid is completely mixed in any cross-section at any point but it experiences no axial mixing ie. Corresponding to the complete and plug flow reactors.

DC d r C Ideal batch. Here polymerization and conversion reactions are performed in noncatalytic mode. The reaction takes place at 3 atm.

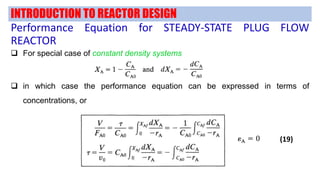

Principles of Operation In the production of viscous polymeric materials it is often desired to operate continuously in order to eliminate batch-to-batch variations and produce a consistent product at all times. Formation rate of R is empirically correlated by the equation B A A B R C C C C r 1 05 1 rR in molLh CA and CB in molL The plug flow reactor is fed with a flow rate of 200 kmol A h and the feeding is 50 A and 50 B. Design of Ideal Reactors Plug-flow reactor PFR A plug-flow reactor PFR may be used for both liquid-phase and gas-phase reactions and for both laboratory-scale investigations of kinetics and large-scale production.

STIRRED TANK REACTORS 1-1 GAS-PHASE PLUG-FLOW TUBULAR REACTORS THAT PRODUCE TRIETHANOLAMINE FROM ETHYLENE OXIDE AND AMMONIA Triethanolamine is produced from ethylene oxide and ammonia at 5 atm total pressure via three consecutive elementary chemical reactions in a gas-phase plug-flow tubular reactor PFR that is not. GX static mixer used in plug flow reactors for viscous materials. This research involves the use of designperformance equations stoichiometric balance equations using first order kinetic reaction process and the condition applied in mildly exothermic.

Cambridge Reactor Design has applied its twenty years of experience in high-pr essur e chemistry and easy to use softwar e to develop systems for scr eening r eactions and carrying out detailed kinetic studies both quickly and safely. Find read and cite all the research you need on ResearchGate. DC dt r C Position in a PFR is equivalent to time in a batch reactor x C.

Designing a Plug Flow Reactor PFR and a Continuous Stirred -Tank Reactor for the production of Dimethyl Ether from dehydration of methanol raw materials. Find Nonisothermal Plug Flow Reactor-Heat exchangeClick on Run in browser to start the application You will see that following window opens which has input parameters description graphical features and. CASCADE of COMPLETE MIX REACTORS Complete MixReactorin Series n-1 n n1 MU-Departmentof -EnvEng-Enve301 CourseNotes-Dr.

Comparison between laminar flow and plug flow reactor A comparison between the simulation results obtained in the plug flow and laminar flow assumptions was finally performed Figure 10.

Pdf Plug Flow Reactor Model Wikipedia The Free Encyclopedia Praveenkumar Dtv Academia Edu

Plug Flow Reactor Vapourtec Ltd

Pdf Design Of Tubular Reactors In Recycle Systems

Plug Flow Operation An Overview Sciencedirect Topics

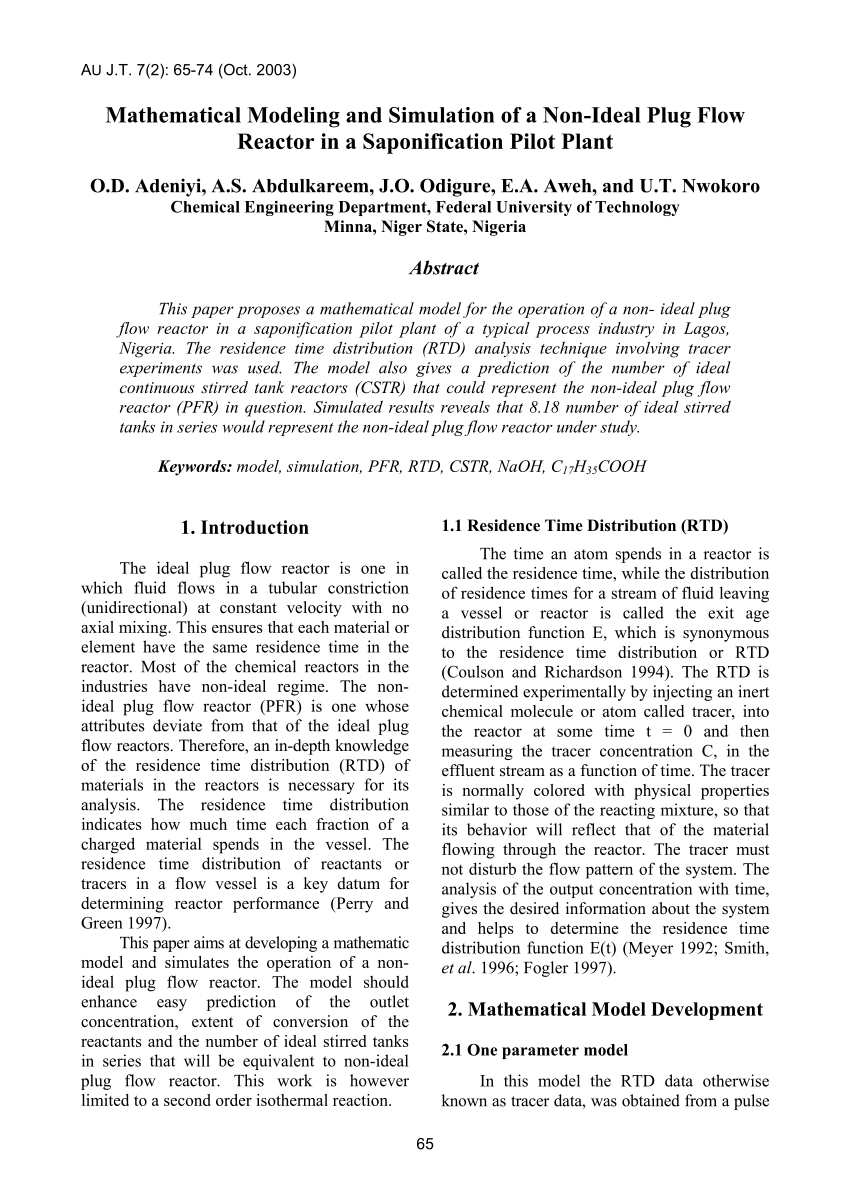

Pdf Mathematical Modeling And Simulation Of A Non Ideal Plug Flow Reactor In A Saponification Pilot Plant

1 4 Continuous Flow Reactors Mole Balances Informit

Plug Flow Reactor Model Wikiwand

Efficient Biogas Production From Cattle Manure In A Plug Flow Reactor A Large Scale Long Term Study Sciencedirect

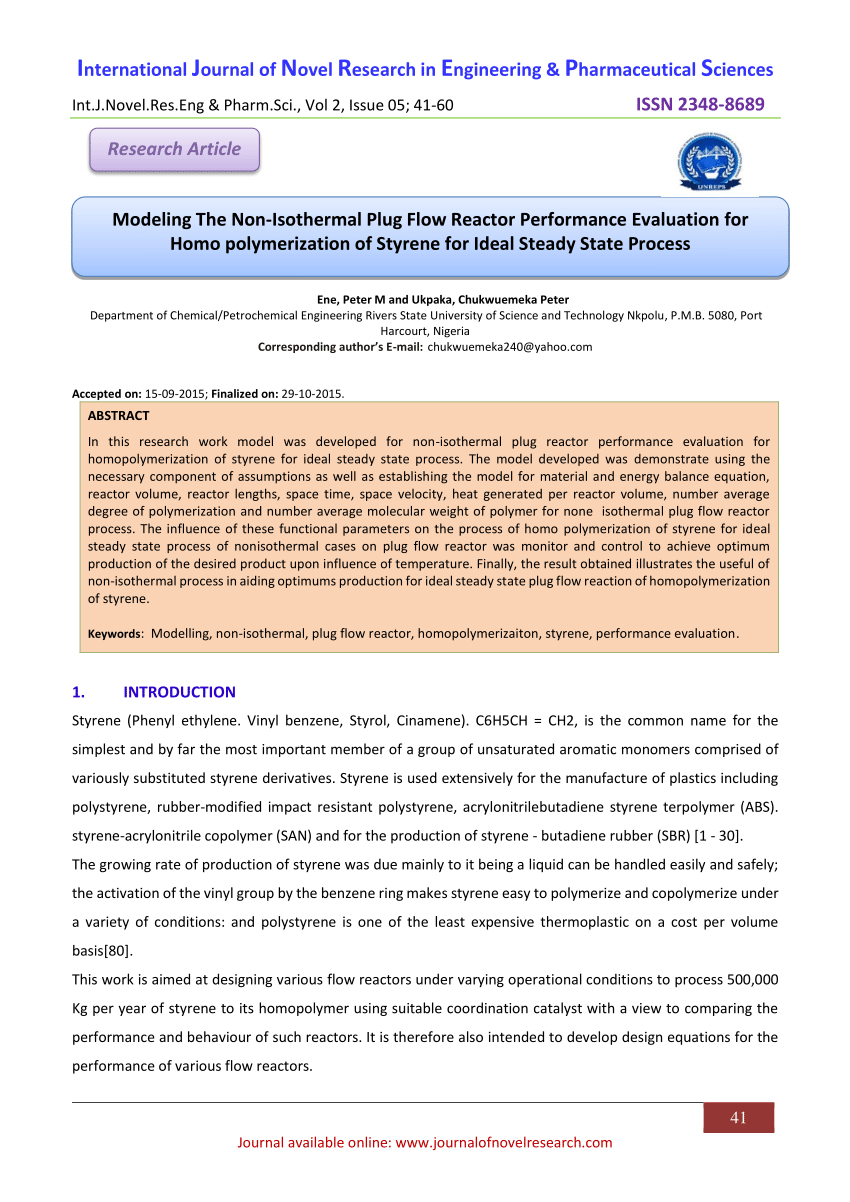

Pdf Modeling The Non Isothermal Plug Flow Reactor Performance Evaluation

Plug Flow Reactor An Overview Sciencedirect Topics

Dry Fermentation Of Manure With Straw In Continuous Plug Flow Reactor Reactor Development And Process Stability At Different Loading Rates Sciencedirect

Pdf Modeling And Process Features Of Plug Flow Reactor With Internal Recirculation For Biomass Pyrolysis Semantic Scholar